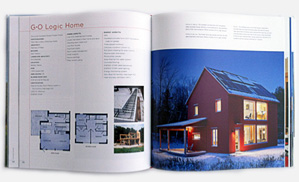

There’s a light steel system on the market that is transforming the construction of residences and commercial buildings. BONE Structure’s prefab components are designed and manufactured in Quebec with the same technology that is used for the precise parts of aircraft and automobiles. This technology offers distinct advantages over traditional building methods.

First, the precision process creates a stable and true structure for the building’s lifetime. State of the art methods allow for simple assembly with minimal tools and no nails. No cutting is required, so waste is eliminated, and construction time is greatly reduced. Within the framework, window and door openings are virtually unlimited.

BONE Structure’s Integrated Measuring System even makes it easy to add windows and doors, or relocate them in the future. Their steel components can span up to 25 feet for rare design freedom. Your choice of exterior siding rests on walls covered with rigid foam insulation panels.

BONE Structure creates chases for all of the systems that make a home function. Heating, ventilation, plumbing, and electrical all run through these highways. The designated spaces save installation time and eliminate energy wasting penetrations in the building envelope. BONE Structure gives new meaning to a machine for living.

The images depict the restaurant-bar Brasseur de Montréal serving as a showcase for this unique prefabricated construction system.

Architects: BONE Structure

Photography courtesy of BONE Structure

share with friends